The Investment in Excellence Pays Off

We have reached the end of our comprehensive series. It covered transforming your self-service condiment station from a high-risk operational headache into a powerful, revenue-generating asset.

This journey has been about making a strategic shift in perspective. Instead of viewing your condiment display as a disposable necessity, recognize it as a critical piece of infrastructure. It directly impacts profitability, hygiene, and customer perception.

Let’s quickly review the core principles we’ve established over the past six posts:

- The Problem (Post 2): Low-cost acrylic and plastic are material and hygienic liabilities. Their vulnerability to scratching harbors bacteria, drives up labor costs, and guarantees early aesthetic failure, pushing customers to competitors.

- The Solution (Post 3): The pivot to powder-coated modular steel is the definitive answer. Its scratch-resistant, non-porous surface is engineered for superior hygiene and offers a 10+ year lifespan.

- The Efficiency (Post 4): Modular design (like PanelRak) is essential for operational excellence. It allows you to seamlessly configure around existing equipment, maximizing every inch of valuable counter space with specialized, clutter-reducing organization.

- The Financial Case (Post 5): The low sticker price of plastic is a myth. A Total Cost of Ownership (TCO) analysis shows that steel provides significant savings. These savings come from avoiding frequent Capital Expenditure (CapEx) cycles and reducing recurring labor OpEx.

- The Revenue Driver (Post 6): An organized, premium display elevates the customer’s sensory experience. It boosts their trust and perception of quality. This directly translates into an increased Willingness-to-Pay (WTP) and a higher likelihood of revisit.

The strategic mandate is clear: It is no longer acceptable to compromise your high-margin beverage program with low-durability, high-risk fixtures.

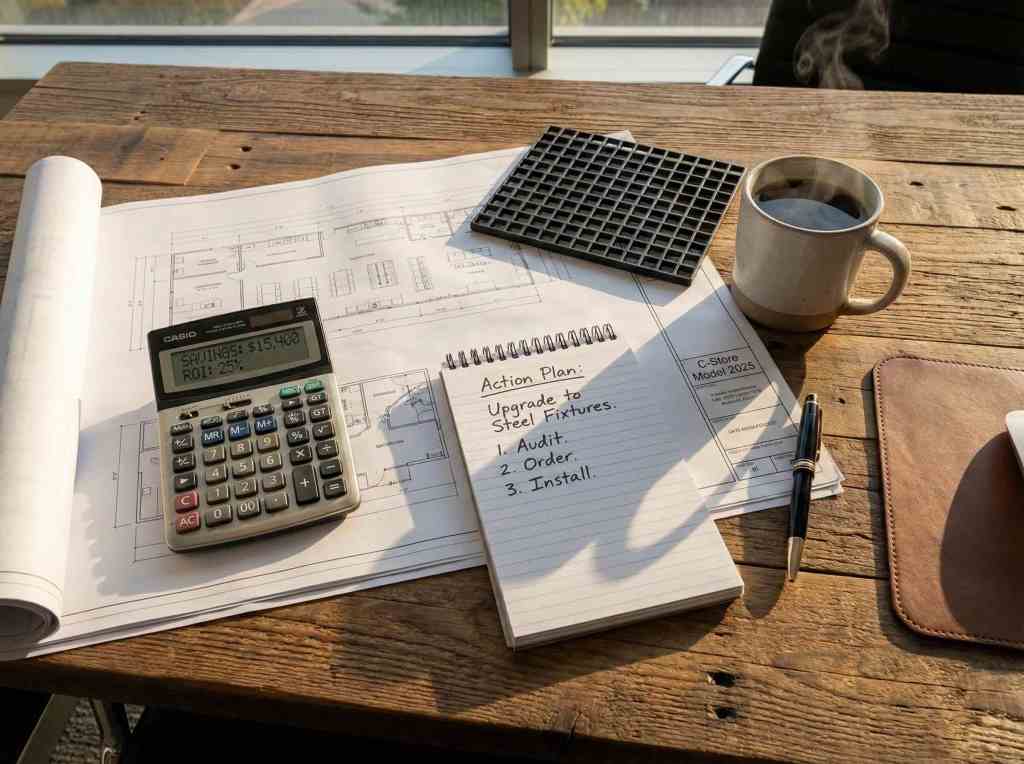

Now, it’s time to move from analysis to action. I am providing you with the step-by-step implementation plan to bring these strategic insights into your stores.

Phase I: Diagnostic and Decommissioning

Before you buy anything new, you must first accurately diagnose the severity of your current problem and prepare for the transition.

What You Should Be Doing

- Conduct a Material Failure Audit: As a Director or Owner, personally inspect your condiment displays. Take photos of all visible scratches, yellowing, and structural warping. Use this evidence to justify the complete decommissioning of all failing plastic units.

- Quantify Hidden OpEx: For your busiest store, time your staff’s cleaning routine for the condiment station during peak hours. Estimate the labor hours spent annually on “careful cleaning” that would be eliminated with durable, easy-to-clean steel.

- Establish a TCO Baseline: Calculate the purchase price, shipping, and installation cost of your current plastic fixtures. Using the 3-5 year lifespan, project the cost of replacements over the next 10 years. This will help you determine your avoided CapEx savings for the new steel system.

Phase II: Strategic Procurement and Design

This phase is about making a calculated, long-term infrastructure investment.

What You Should Be Doing

- Prioritize Material Over Price: Set a non-negotiable standard. Ensure that all new self-service fixtures are made of highly durable materials. They should be scratch-resistant and non-porous. Consider using materials like powder-coated steel. The purchase decision should be based on the lowest Total Cost of Ownership (TCO), not the lowest initial price.

- Optimize Counter Real Estate: Engage with the supplier, like the developers of PanelRak. Configure the modular system around your existing high-value equipment. Include your roller grills, bun cabinets, and specialty coolers. Use the verticality of the modular system to maximize space without increasing your counter footprint.

- Mandate Targeted Organization: Ensure your new system includes specialty baskets. These baskets should be designed specifically for your high-volume C-store items. Examples include dedicated lid holders, syrup bottle racks, and segregated packet areas. This is essential for eliminating clutter and increasing the Perceived Ease of Use (PEOU) for customers.

Phase III: Implementation and Strategic Merchandising

Installation should be viewed as the launch of a new, premium service offering.

What You Should Be Doing

- Deploy Standardized Systems: Utilize the standardized components. Ensure compatibility with pegboard/slat wall hardware. This will help to roll out a consistent and professional look across your entire store fleet. Standardization simplifies staff training and maintenance protocols.

- Set the Premium Look: Take advantage of the structural stability of the steel system. Integrate high-quality, professional signage like graphic headers. This approach reinforces the premium quality of your beverage program.

- Institute a Merchandising Cycle: Leverage the system’s modular flexibility for dynamic retail. Schedule monthly or quarterly merchandising refreshes to move impulse items onto the display, driving attachment sales to high-margin beverages. Use the fixture as your “silent salesperson.”

- Monitor WTP and Revisit Rates: In stores where the upgrade has occurred, track customer satisfaction data. Measure the average basket size during the beverage daypart. Monitor customer revisit intentions as well. The premium fixture should generate a measurable uplift in all these areas.

The Bottom Line: Securing Your Next Decade of Profitability

Your convenience store’s coffee program is one of your most valuable assets. Allowing its final impression, the “last mile” condiment station, to be dictated by cheap, short-lived plastic, is financially and operationally irresponsible.

We have seen how a strategic investment in a durable, engineered modular system, such as PanelRak, is not an expense. Instead, it is a long-term infrastructure solution. It guarantees superior hygiene and optimizes labor. It also acts as a powerful marketing tool to build customer trust and elevate perceived value.

The decision to upgrade your self-service fixtures is a foundational commitment to excellence. It’s a declaration to your customers that you value their experience and their health. This commitment will be rewarded with increased loyalty, higher sales, and a stable, high-performance profit center for the next decade.

The time to stop managing decline and start investing in enduring excellence is now. Secure your infrastructure, secure your margins, and secure your competitive edge.

Call to Action: Don’t let your high-margin beverage program suffer another year of plastic failure. Begin by calculating your current TCO. Then contact a specialist in modular steel organizing systems (PanelRak) today. They will design a durable, revenue-enhancing layout for your highest-traffic stores.

Leave a comment